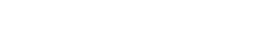

Welcome to KUZEY GLOBAL

Your Expert in Thermoforming Plastic Food Packaging machine and sheet extrsuion lines

When it comes to thermoforming plastic food packaging, the choice of thermoforming machine and extrusion line is crucial. At Kuzey Global , we use high-quality technology and materials in production Our KG and CMK Series Thermoroming machines and Extrusion lines are at the forefront of advanced technology, offering a wide forming area and allowing us to reach high capacities efficiently. Whether you need packaging for small individual portions or large and heavy food items, our machines can handle it all with ease.

One of the key strengths of our machines is their ability to handle PET food containers with exceptional precision. The high cutting power ensures that every PET container produced meets the highest quality standards, providing reliable packaging for your valued products.

Our tilting and station thermoforming machines offer the most suitable solutions at high standards for packages produced with PP, PS, PET raw materials.

Kuzey Global are committed to delivering top-quality thermoforming plastic food packaging machines and extrusion lines that not only meet industry standards but also exceed your expectations. Our experienced team is ready to collaborate with you to bring your packaging ideas to life. Contact us today and let’s embark on a successful packaging journey together!

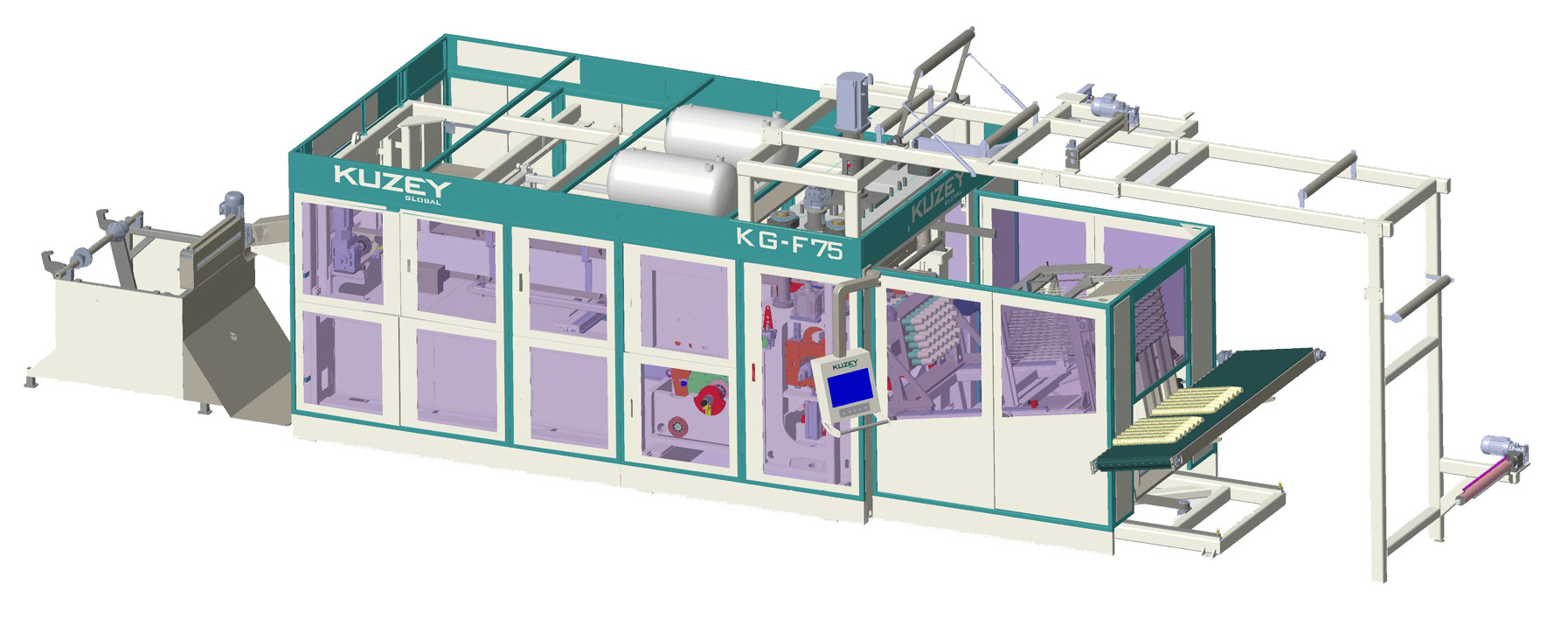

KG SERIES

In-mould forming & cutting

KG Serie; Thermoforming machines reach high capacities with wide forming area and high technology moreover is the most suitable machine for manufacturing PET products with high cutting force.

CMK SERIES

Forming and steel rule cutting

EXTRUDER TECHNOLOGY

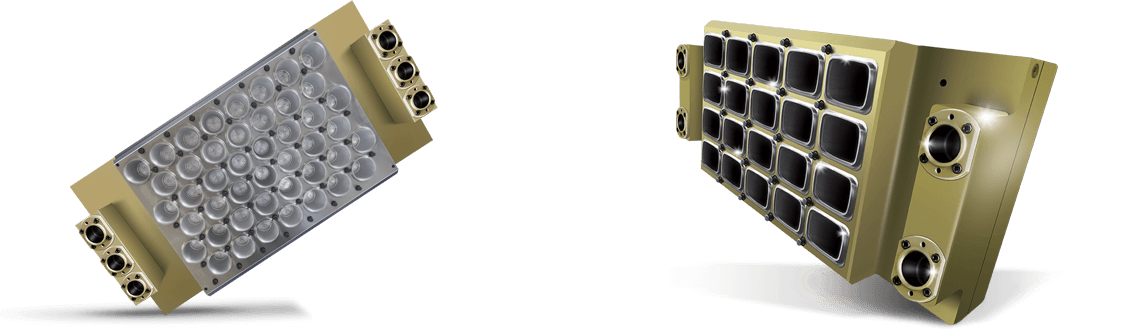

MOLDS

USTAFORM design in-mould forming & cutting, and cut-in-place thermoforming moulds for thermoforming machines. Manufacturing section is equipped with European CNC machines controlled by experienced technical personnel to shape mould projects according to customer demands.

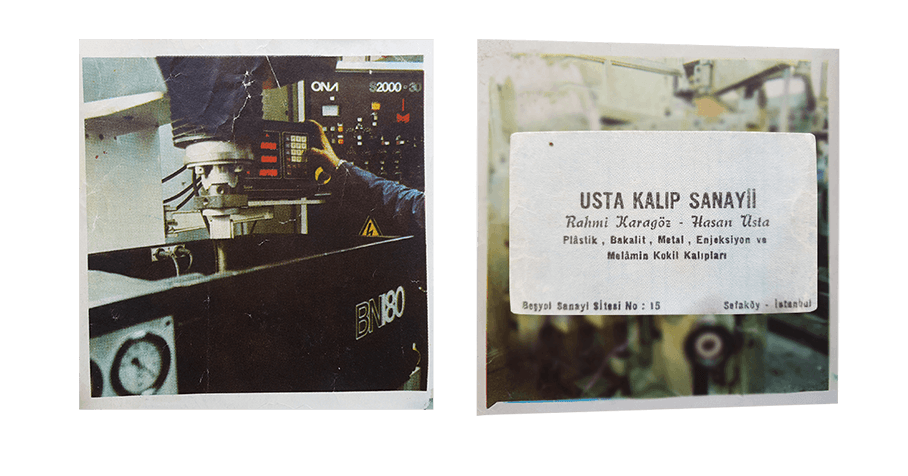

ABOUT US

Since 1970, KUZEYGLOBAL has been a premier expert in Thermoforming Plastic Food Packaging machines and sheet extrusion lines, proudly based in Turkey. As the exclusive provider of turnkey projects under its own brand, KUZEYGLOBAL stands out for its unwavering commitment to innovation, superior quality, and global service.

Explore our product range, featuring:

- KG Series: In-mould forming & cutting type machines and equipment

- CMK Series: Forming and steel rule cutting type machines and equipment

- Extruder lines and equipment

- Offset Printing machines

Our use of state-of-the-art technology and premium materials ensures the production of high-quality machines. The KG and CMK Series Thermoforming machines and Extrusion lines lead the industry with advanced features, providing a generous forming area and efficient high-capacity production. Whether your packaging needs involve small portions or large, heavy food items, our machines handle it all effortlessly.

Our machines excel in precision for handling PET food containers, ensuring adherence to the highest quality standards. Meanwhile, our tilting and station thermoforming machines maintain superior standards for packaging produced with PP, PS, and PET raw materials.

At KUZEYGLOBAL, we are committed to delivering top-quality thermoforming plastic food packaging machines and extrusion lines that surpass industry standards. Collaborate with us today to transform your packaging ideas into successful reality!

Words That Describe Us

Pet Pp Ps Thermoforming Sheet Making Machine, Apet Thermoforming Sheet Making Machine, Pet Pp Ps Co-Ex Thermoforming Sheet Line, Pet Pp Ps Co-Extrusion Line, Apet Avoh Pe Sheet Extrusion Line, Kuzey Thermoforming Machine, Food Packaging Machine, Pp Pet Ps Cup Thermoforming Machine, Sauce Cup Water Drinking Cup Thermoforming Machine, Thermoforming Machine for Beer Cups, Beverage Cups, APET Flake Filter for Extrusion Line, Melt Pump for Extrusion Line, Tdie for Extrusion Line, Mold for Tilting Thermoforming Machine, Dosing System for Extrusion Line, Thermoforming Packaging Solutions, Food Packaging Technology, High-Speed Packaging Machines, High-Speed Thermoforming Machines, High-Speed Thermoforming Tilting Machines, Vacuum Packaging Machines, Vacuum Thermoforming Machine, Die Cutting Thermoforming Machine, Steel Rull Theroforming Machine, Tray Plate Thermoforming Machine, Container Clamshell Lid Egg Vial Thermoforming Machine, Offset Printing Machines for Cups, Pp Pet Ps Cup Printing Machine, High-Speed Offset Printing Machine, Three Station Thermoforming Machine, Four Station Thermoforming Machine, Lid Thermoforming Machine, Offset Cup Printing Machine Manufacturer, Offset Printing Machine Turkey

CONTACT US!

Follow Us!

Get notified of updates!