Welcome to KUZEY GLOBAL

Your Expert in Thermoforming Plastic Food Packaging machine and sheet extrsuion lines

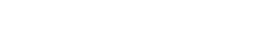

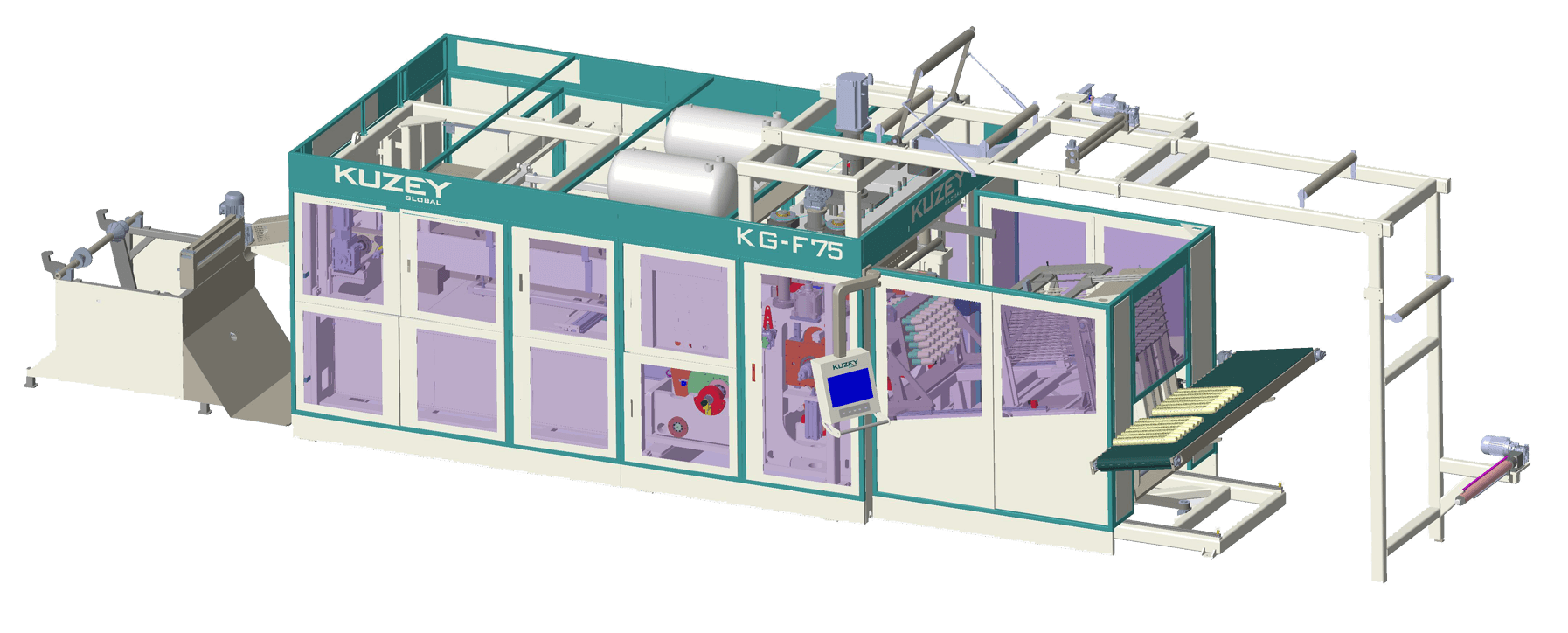

When it comes to thermoforming plastic food packaging, the choice of thermoforming machine and extrusion line is crucial. At Kuzey Global , we use high-quality technology and materials in production Our KG and CMK Series Thermoroming machines and Extrusion lines are at the forefront of advanced technology, offering a wide forming area and allowing us to reach high capacities efficiently. Whether you need packaging for small individual portions or large and heavy food items, our machines can handle it all with ease.

One of the key strengths of our machines is their ability to handle PET food containers with exceptional precision. The high cutting power ensures that every PET container produced meets the highest quality standards, providing reliable packaging for your valued products.

Our tilting and station thermoforming machines offer the most suitable solutions at high standards for packages produced with PP, PS, PET raw materials.

Kuzey Global are committed to delivering top-quality thermoforming plastic food packaging machines and extrusion lines that not only meet industry standards but also exceed your expectations. Our experienced team is ready to collaborate with you to bring your packaging ideas to life. Contact us today and let’s embark on a successful packaging journey together!

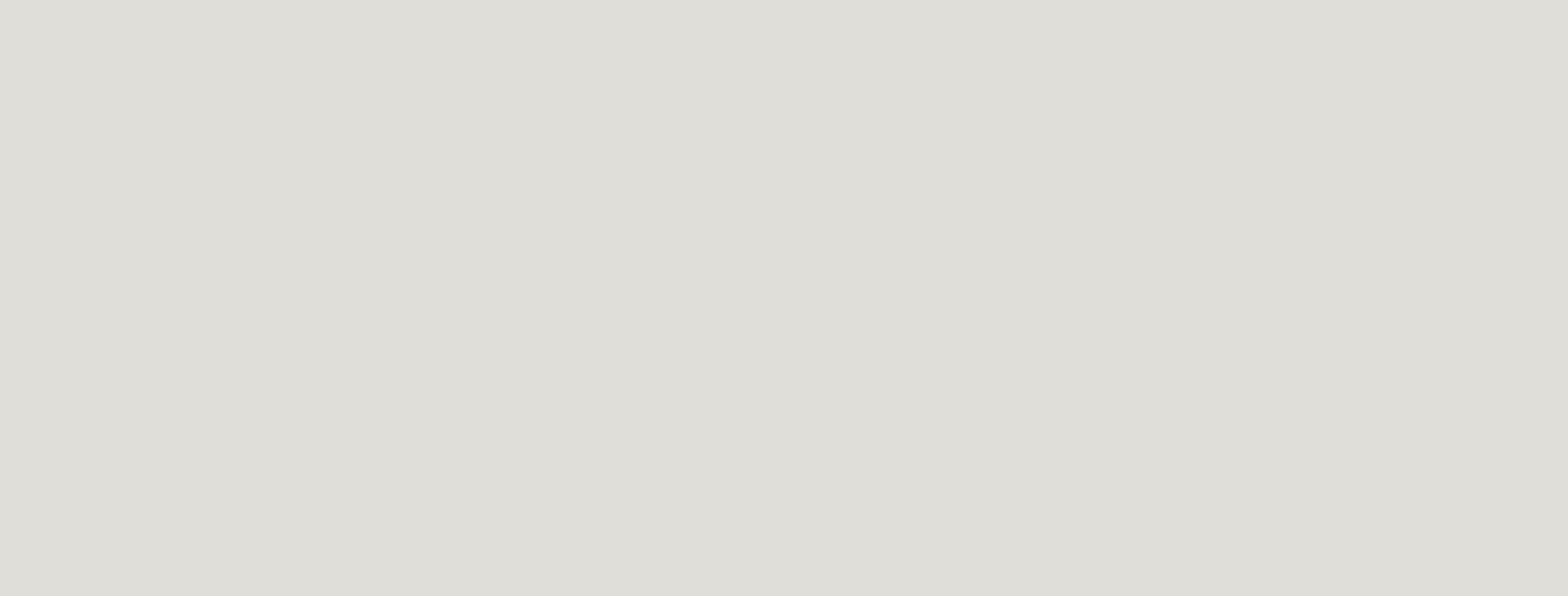

KG Серии

Формование и резка

Ceрии KG Термоформовочных машин обеспечивают высокую производительность с использованием передовых технологий и широкой зоны формования. Кроме того, высокая мощность вырубки оборудования является наиболее подходящей машиной для производства изделий из ПЭТ.

СMK серии

Формирование и стальные ножные резки

ЭКСТРУДЕНРНАЯ ТЕХНОЛОГИЯ

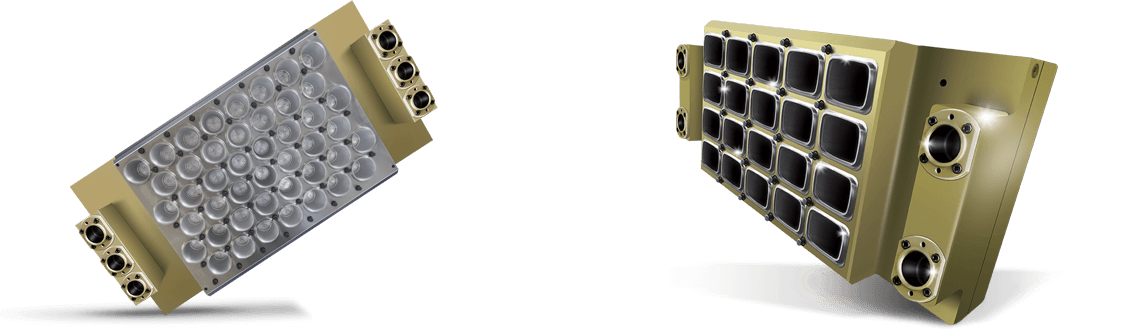

ПРЕСС-ФОРМЫ

Дизайны USTAFORM предназначены для формовки и резки пресс-форм, а также пресс-формы для термоформования в термоформовочных машинах. Производственная секция оснащена европейскими станками с ЧПУ, которыми управляет опытный технический персонал для формирования проектов пресс-форм в соответствии с требованиями заказчика.

О КОМПАНИИ

Наша производство началось с пресс-форм в 1970 году, фирма называлась USTA KALIP, после под названием CAG MAKINA начали производить термоформовочные оборудования в 1995 году. В настоящее время наша деятельность продолжается под названием KUZEY GLOBAL.

KUZEY GLOBAL вкладывая большие усилия в исследования и разработки. стремится стать одной из ведущих компаний в международной сфере. В сфере Термоформовки и Упаковки наша фирма единственная в Турции которая производит проекты под ключ.

В 2015 году началось производство экструдерной линии, и данное оборудование так же стала частью нашего заводского производства. В настоящее время наша компания продолжает производство оборудований и пресс-форм под маркой KUZEYGLOBAL.

Читать дальше…

Свяжитесь с нами

Подписывайтесь На наши Сетевые Новости!

Будьте в курсе всех новостей Kuzey Global!